What Are the Challenges of Running a Factory?

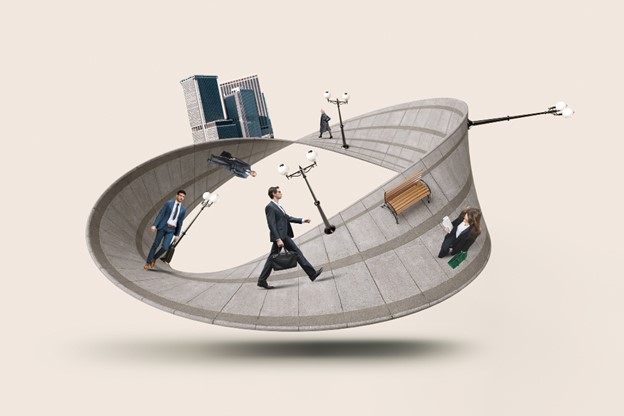

There is more to running a factory than the noise of machines and the constant activity of workers. It also involves logistics, technology, and human management.

We’ll explore the complexities of factory owners and managers’ challenges, revealing potential solutions and strategies for success.

Understanding the Operational Landscape:

The operation of a factory involves a variety of challenges that require a delicate balance to ensure smooth operation. Manufacturing process efficiency and success are dependent on every aspect, from supply chain disruptions to workforce management.

Aspects of Manufacturing Process

- Supply Chain Vulnerabilities:

Among the most significant challenges factories face is the vulnerability of their supply chains. External factors like geopolitical issues, natural disasters, or global pandemics can disrupt the supply chain, leading to delays in production and increased costs.

To mitigate these risks, supply chains must be resilient and diversified.

- Technology Integration and Upgradation:

Staying ahead of the curve becomes increasingly challenging for factory owners as technology advances. Integrating new technologies and upgrading existing systems is necessary for maintaining efficiency and competitiveness.

This process, however, comes with its own set of challenges, including initial investment costs and employee training.

- Workforce Management:

The management of a diverse workforce with varying skill sets, backgrounds, and expectations poses its own challenges.

In addition to ensuring employee safety, addressing labor shortages, and fostering a positive work environment, effective workforce management plays a crucial role in factory productivity.

- Compliance and Regulations:

There are a wide variety of regulations and compliance standards that govern the manufacturing industry. For a factory to operate within the legal framework and avoid fines and legal complications, constant vigilance and adaptation are required.

- Energy Costs and Sustainability:

As energy costs rise and sustainability becomes increasingly important, factories are being required to reduce their environmental footprint. Achieving energy efficiency while balancing operational costs is a delicate task requiring strategic planning and investment.

- Market Fluctuations and Demand Forecasting:

Managing market fluctuations and accurately forecasting demand are perpetual challenges for the manufacturing industry. It is possible to overestimate or underestimate demand, leading to excess inventory or stock outs that negatively impact revenue and customer satisfaction.

Conclusion

The challenges that factories encounter are opportunities for growth and improvement, rather than roadblocks.

Get operational excellence with VMS Consultants – One of the leading Industrial infrastructure in Gujarat. With expertise in Engineering, Architecture, and Project Management Services, VMS is committed to transforming challenges into triumphs.

Explore the possibilities with VMS Consultants – your partner in success.