Equipotential Bonding

“Equipotential Bonding” itself explain its meaning, Equivalent (Equal) – Potential (Voltage)”. In Electrical system Earthing and EPB (Equipotential Bonding) plays very important role for safety and reliability of system. We all know significance of Earthing but in our regular practice, Equipotential Bonding have been overlooked. This article will describe Equipotential Bonding and its significance.

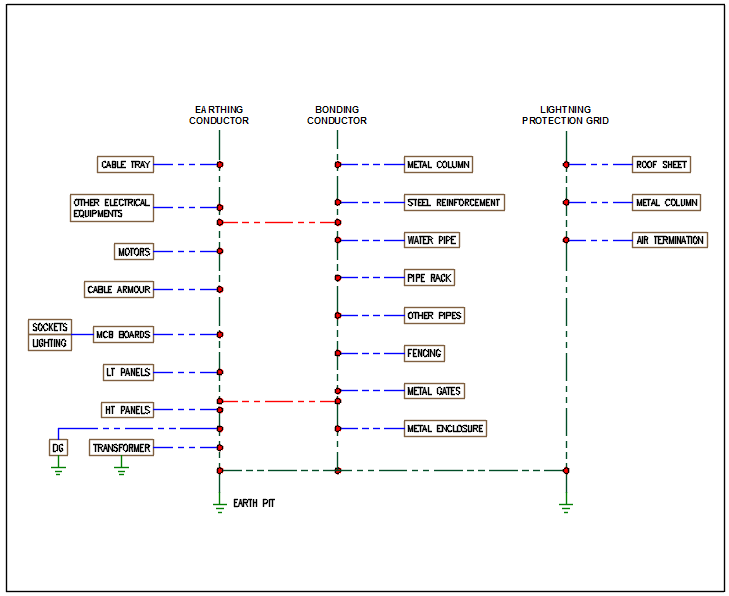

EPB is nothing but connecting all Metal/conductive parts together with low resistive path to earth. In earthing system, all electrical equipments or any other current carrying parts are connected to earthing network while in EPB, even Non-Electrical Metallic equipment like building column, reinforcement, Roof, Pipes, Enclosures, Gates, etc. are being connected to earthing system with low resistive path. EPB is part of earthing system, lightning protection and surge protection system. In a sense of electrical aspect we can say that EPB reduce the touch and step potential level.

When to Parts are having Potential difference and any person make contact both parts at some moment, it can be hazardous. Below are few example which can explain signification of EPB.

- Potential difference can be possible due to some faulty equipments for example faulty geezer or water cooler lead to raise potential level of pass current through pipes/faucet. Connecting pipe network to earthing system can neutralise potential difference and lead to operation of earth leakage devices.

- Static charges can be develop in fluid carrying pipes, mechanical equipments etc. and static charges in industrial environment can be very dangerous especially in Hazardous area. With proper bonding, this static charges can be grounded.

- Supposing in one industrial shed, bonding of metal component of building (roof and cladding sheet) has not been connected with other building components like pipe racks, Pipes etc. In case of lightning strike on Metal roof there will be huge potential difference between Metal shed and other components within building which are near to building envelope. In such scenario there will be sparking between building sheets and other equipments could be taken place.

If all these systems are bonded together, there won’t be any potential differences hence no current shall be flown between two bodies.

It is essential to provide bonding and earthing of incoming water lines and gas line pipes at entrance point, so any lightning surges or static charge can be neutralised. Any isolated Metallic parts like metal faucet connected to PVC pipes, isolated metallic storage enclosure etc. not required any Bonding.

In Industrial premises, this become more important because of size of premises and more complex metal equipments. Larger facility is more susceptible for lightning strike and indirect surges. Industrial premises shall have higher fault current, hazardous environment and in absence of EPB there are more chances of developing unsafe conditions.

Earthing and Bonding are an essential part of any electrical system. It ensures personnel safety and reliability of electrical system. As an engineering company, VMS Engineering and Design services Pvt ltd is adhering all safety aspect and specifying EPB, earthing system and LPS as per latest Indian and IEC Standards and translate them as Notes, Specifications, Layouts and Installation details. For example, below is sample Riser diagram of EPB and Earthing system.