Choosing Pre-Engineered Buildings vs. Conventional Steel Structures for Industrial Projects

Industrial buildings are special types of structures that are designed to accommodate the unique needs of various industrial processes, including manufacturing, storage, and transportation. Industrial structures have different features as they are required to cater to the needs of manufacturing businesses and to ensure efficient production through the processes stated above.

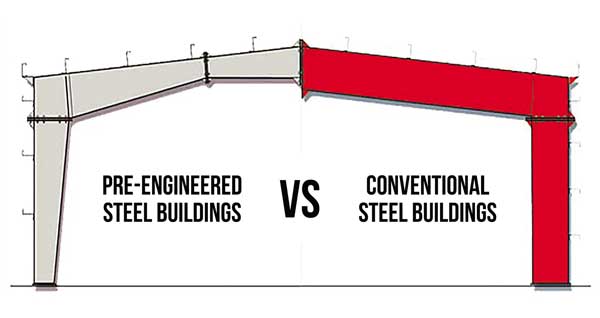

Pre-engineered buildings, better known as PEBs, have taken over conventional steel structures in recent years. They are best known as an alternative to conventional steel buildings. Pre-engineered buildings have been so popular in the industry due to their advantages like faster work completion, ease of installation, and cost-effectiveness.

In this blog, we will learn the major differences between the traditionally built industrial steel structures and the PEBs for industrial construction.

Traditionally Built Steel Structures for Industrial Construction

Industrial buildings have been built for ages, even before the existence of some modern techniques. Primarily, the industrial structures were constructed using the conventional methods of bolting and welding. The components of the industrial building structures, such as columns, beams, and trusses, are fabricated on site from scratch and designed according to the specifications and design requirements of the structure. Conventional steel structures for industrial construction are usually time-consuming as they are prepared from scratch.

However, the quality of the conventional structures may vary as their monitoring is difficult.

Pre Engineered Buildings (PEBs) for Industrial Structures

Pre-engineered buildings, also known as pre-fabricated structures, are structures built with components that are manufactured off-site. The prefabricated components are brought and installed on the construction site, making the process faster, more accurate, and more cost- efficient. With advantages such as cost, time, and optimized use of resources, pre-engineered structures offer flexibility in design and are easier to install and remove. Hence, they are popular due to the ease of work in the construction industry for building industrial structures.

Pre Engineered Buildings vs. Conventional Steel Structures for Industrial Buildings

|

Factor |

PEB |

Conventional Structure |

|

Speed |

Pre-Engineered Buildings are built at a quicker pace as their components are prefabricated. |

Relatively slower speed of construction due to on-site fabrication of building components. |

|

Customization |

The Pre-fabricated Buildings are easy to build but are designed to serve specific design requirements. Hence, they are not customizable. |

The conventional structures can be fabricated however the client wants, as they aren’t prefabricated. They are more flexible in terms of design and customization. |

|

Cost |

Pre-fabricated industrial structures offer cost efficiency due to the elimination of long procedures and labor requirements. Also, their construction process is streamlined, which could be one of the reasons for its lesser cost. |

Conventional structures are frequently more expensive than pre- engineered structures because they are fabricated on-site and require more resources than PEBs. |

|

Durability |

PEBs are durable, as are conventional steel structures. This is because the durability of the structures depends on the quality of construction, the design, and the quality of material used. |

Both the PEBs and the traditionally built steel structures for industrial buildings are designed to withstand harsh environments and the intended load. So, we can say both are durable. |

| Maintenance | PEBs are designed for low maintenance and do not require much of it. | Conventionally designed steel structures require more maintenance due to their complex designs and the room for customization. |

Wrapping Up

Overall, PEBs may be more suitable for industrial construction projects that require a quick turnaround time and a standardized design, while conventional structures may be more suitable for projects that require more customization and flexibility in design. However, the specific needs and constraints of each project should be carefully evaluated before making a decision.