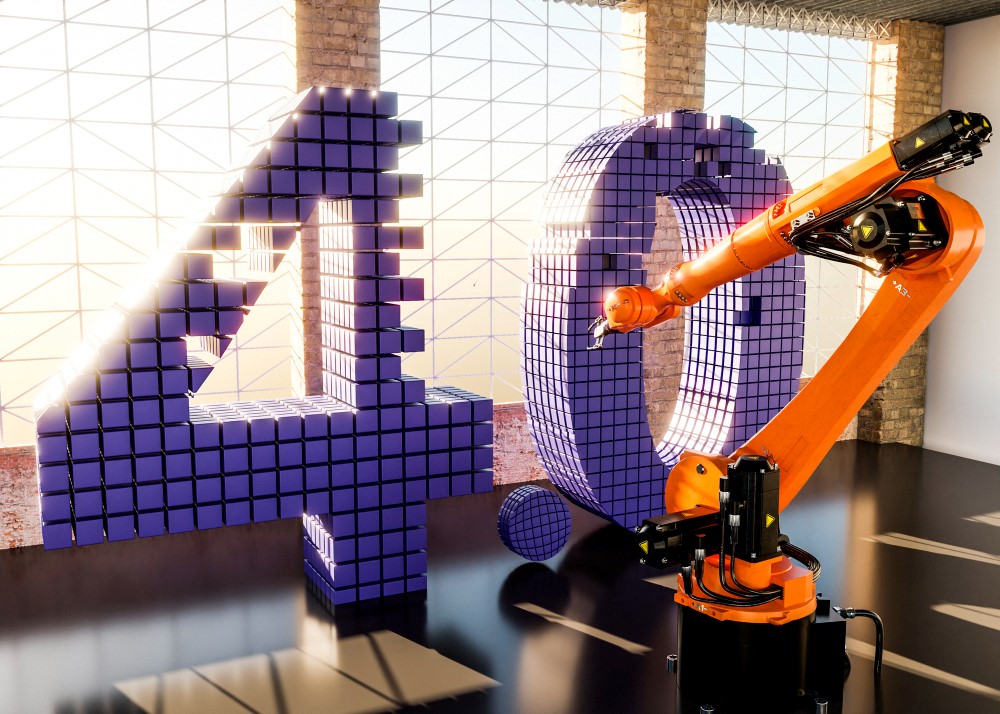

A Guide to Implementing Industry 4.0 and Smart Manufacturing

Industry 4.0 and smart manufacturing are rapidly emerging as transformative forces in the fast-paced field of industrial evolution, in which innovation plays a significant role in maintaining a competitive advantage.

VMS Consultants provides the expertise and experience needed to make sure you are up to date with the latest trends and implement the right strategies for Smart Manufacturing and Industry 4.0 in Ahmedabad, Gujarat.

Our aim in this article is to simplify and explain these trending concepts, as well as to illustrate their impact on industrial processes.

What is Smart Manufacturing?

A smart manufacturing process combines traditional manufacturing processes with cutting-edge technology. At its core, it’s about leveraging real-time data and advanced analytics to improve efficiency, quality, and overall productivity.

The integration of Smart Manufacturing technologies brings forth a paradigm shift in how industries approach production.

3 Pillars of Smart Manufacturing

- IoT Integration: The Internet of Things (IoT) forms the foundation of Smart Manufacturing, connecting devices, sensors, and machines. As a result of this interconnected ecosystem, data exchange and communication become seamless.

- Data Analytics: Smart Manufacturing relies heavily on data analytics to extract meaningful insights from massive amounts of data. To optimize decision-making processes, predictive analytics, machine learning, and artificial intelligence are used.

- Automation and Robotics: Robots perform repetitive tasks and automate complicated processes in Smart Manufacturing. It improves efficiency and ensures accuracy and consistency.

What is Industry 4.0?

Smart Manufacturing lays the foundation for Industry 4.0, resulting in the Fourth Industrial Revolution. In addition to the factory floor, it encompasses the entire value chain and blurs the boundaries between the physical and digital worlds.

Industry 4.0 is characterized by:

- Cyber-Physical Systems: Interconnected and intelligent systems created by integrating physical systems with digital technologies.

- Big Data and Analytics: Analyzing and making real-time decisions based on big data, enabling continuous improvement.

- Horizontal and Vertical Integration: Efforts to integrate processes horizontally along the value chain and vertically from shop floor to management.

Benefits of Smart Manufacturing and Industry 4.0 Integration

- Enhanced Efficiency: Real-time monitoring and optimization lead to increased operational efficiency.

- Improved Quality: Data-driven insights enable proactive quality control, reducing defects and enhancing product quality.

- Agile Response: The ability to adapt quickly to market changes and evolving customer demands.

- Resource Optimization: Smart Manufacturing and Industry 4.0 facilitate better resource utilization, reducing waste and costs.

Intelligence Will Drive The Industry of The Future

In conclusion, Smart Manufacturing and Industry 4.0 are not just concepts; they are the future of industrial processes. The integration of intelligence into manufacturing paves the way for unprecedented efficiency, agility, and innovation.

Collaboration with industry experts like VMS Consultants, leading engineering consultants in Gujarat, becomes the roadmap that helps industries take part in this journey.

Ready to unlock the potential of Smart Manufacturing and Industry 4.0 for your business? Consult with VMS Consultants today and get started on a journey towards a future where your industry thrives on intelligence and innovation.

Your path to the future starts with VMS Consultants.