How to Optimize Warehouse Layouts for E-commerce Fulfillment?

Warehouse management plays a critical role in ensuring that orders are fulfilled accurately and quickly for e-commerce businesses. Due to the increasing popularity of online shopping in India, businesses need to optimize their warehouse layouts to meet customer expectations.

Well-designed layouts can significantly boost efficiency, and VMS Consultants, a premier engineering consultancy in Ahmedabad, can provide the expertise needed to achieve this.

This article explores key strategies for optimizing warehouse layouts for e-commerce fulfillment.

Key Steps to Optimize Your Warehouse Layout

1. Understand Your Product Flow

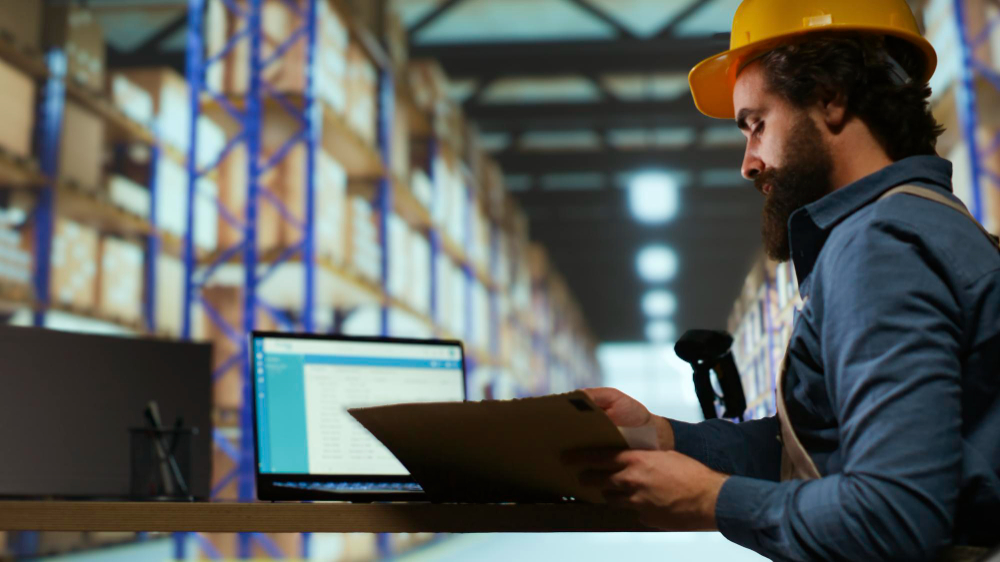

Understanding your product flow is the key to an optimized warehouse layout. This involves analyzing how products move through your warehouse, from receiving to storage, picking, packing, and finally shipping. By mapping out this flow, you can identify bottlenecks and areas of inefficiency.

For e-commerce, where speed is crucial, the warehouse layout must be designed to minimize unnecessary movement. Products that are frequently ordered should be stored closer to the packing and shipping areas to reduce the time and effort required for picking.

On the other hand, slower-moving items can be placed in less accessible areas to free up valuable space for high-demand products.

2. Implement ABC Analysis

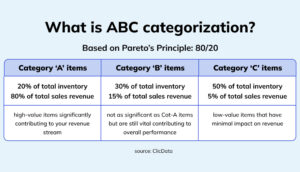

ABC analysis is a popular inventory management technique that categorizes products based on their importance.

‘A’ items are the most valuable and frequently ordered products,

‘B’ items are of moderate value and demand, and

‘C’ items are the least valuable with low demand.

By implementing ABC analysis in your warehouse layout, you can prioritize the placement of ‘A’ items in the most accessible locations. This ensures that your most critical products are easy to pick and pack, leading to faster order fulfillment. Meanwhile, ‘B’ and ‘C’ items can be stored further away from the central workflow, optimizing the use of space and resources.

3. Design Efficient Aisle Layouts

The aisle layout plays a significant role in optimizing warehouse efficiency. It is important that aisles are wide enough for equipment such as forklifts and pallet jacks, but not so wide that they waste valuable floor space.

There are several aisle configurations to consider, and VMS Consultants can assist in selecting the most effective design. Straight aisles, serpentine aisles, and diagonal aisles are some of the most common aisle layout designs.

Choosing a layout depends on the size of your warehouse and the types of products you sell.

4. Optimize Storage Solutions

Optimizing warehouse layouts requires effective storage solutions. It is important to choose the right type of storage for your products based on their characteristics.

For example, small, lightweight items may benefit from bin shelving, while large, bulky products may require pallet racking.

E-commerce can have a wide variety of products, so consider combining storage solutions to handle different types of inventory. Additionally, vertical storage systems can maximize warehouse capacity by utilizing the warehouse’s height.

5. Streamline Picking Processes

In a warehouse, order picking is one of the most labor-intensive processes, and optimizing this process is key to improving efficiency. Technologies such as pick-to-light and voice picking can significantly enhance order picking accuracy and speed.

The pick-to-light system uses illuminated displays to direct pickers to the correct locations, while the voice picking system uses voice commands. Both systems eliminate the need for paper picking lists and minimize errors. By grouping similar orders together (batch picking), pickers can reduce the number of trips they take during the picking process.

6. Focus on Ergonomics

Employee productivity is closely linked to workplace ergonomics. A warehouse layout that prioritizes ergonomics can reduce fatigue, minimize the risk of injuries, and improve overall efficiency. This involves designing workstations and storage areas that minimize the need for employees to bend, reach, or lift heavy items.

For example, placing frequently picked items at waist height can reduce the strain on employees, while adjustable packing stations can accommodate workers of different heights. Providing adequate lighting and clear signage can also enhance the working environment, making it easier for employees to navigate the warehouse and perform their tasks efficiently.

7. Integrate Technology for Real-Time Tracking

The integration of technology is essential for modern warehouse management. Real-time tracking systems, such as RFID (Radio Frequency Identification) and WMS (Warehouse Management Systems), provide visibility into inventory levels and the location of products within the warehouse.

These technologies enable businesses to monitor inventory in real-time, reducing the chances of stockouts or overstocking. They also support efficient order processing by automatically updating inventory records as products are picked, packed, and shipped.

8. Plan for Scalability

As your e-commerce business grows, your warehouse needs will evolve. The warehouse layout should be scalable, so that it can accommodate future growth without having to be completely redesigned. It involves designing flexible spaces that can be reconfigured easily.

Consider the potential for expanding your storage capacity, adding new picking zones, or incorporating additional automation systems. By planning for scalability, you can avoid disruptions to your operations and ensure that your warehouse remains efficient as your business scales.

Partner with VMS for Optimal Results

The process of optimizing warehouse layouts for e-commerce fulfillment requires careful planning and consideration of a variety of factors.

For expert guidance in optimizing your warehouse layout, consider partnering with VMS Consultants, Leading Engineering Consultancy in Ahmedabad. With extensive experience in Engineering Architecture & Project Management Services, we can help you design and implement solutions that drive efficiency and growth.

Contact us today to learn more.