The Importance of Noise Control and Acoustic Design in Manufacturing Facilities

Noisy machinery and production lines are more than just an inconvenience in manufacturing; it’s a factor that can impact productivity, employee well-being, and even the bottom line. Factory workers face daily exposure to loud and potentially hazardous noise levels.

Finding the right engineering consultancy in Ahmedabad can help manufacturing facilities identify the sources of noise pollution, develop effective noise control strategies, and implement solutions that create a safer and more productive workspace.

This article explores the importance of noise control and acoustic design in manufacturing facilities, shedding light on innovative solutions that balance the demands of industry with the need for a harmonious and efficient workspace.

Understanding the Impact of Noise in Manufacturing

Manufacturing facilities are subject to far-reaching effects of noise. It’s not just an annoyance. Excessive noise levels can lead to stress among employees, communication barriers, and even a decline in overall workplace safety.

Additionally, noise pollution can negatively impact the environment and the surrounding community.

Key Considerations in Noise Control and Acoustic Design

1. Noise Source Identification: The first step in effective noise control is identifying the sources. This includes machinery, equipment, ventilation systems, and even human activities.

2. Engineering Controls: Implementing engineering controls such as sound barriers, enclosures, and vibration isolators can mitigate noise at the source, preventing it from spreading.

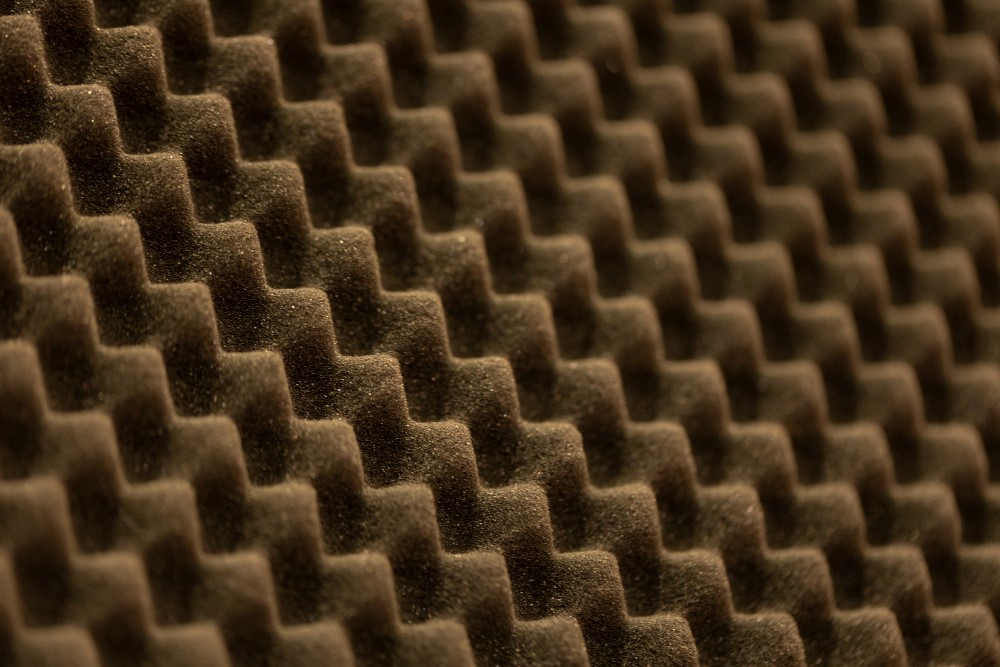

3. Material Selection: Choosing materials with sound-absorbing properties for walls, floors, and ceilings contributes to a quieter and more comfortable working environment.

4. Maintenance Practices: Regular maintenance of machinery and equipment helps prevent wear and tear, reducing the likelihood of noisy malfunctions.

Understanding Noise Sources in Manufacturing Facilities

1. Machinery and Equipment: Machines and equipment in manufacturing facilities often contribute to noise pollution.

2. Processes and Operations: Certain manufacturing processes generate inherent noise, which can vary depending on the industry.

3. Poorly Designed Spaces: Inadequate acoustic design of the workspace can amplify noise levels, creating a challenging environment for employees.

Innovative Solutions for Noise Reduction in Manufacturing Facilities

1. Active Noise Control (ANC): ANC systems use technology to counteract noise by producing sound waves that cancel out undesirable noise, creating a more tranquil environment.

2. Sound Masking: Introducing background noise, or sound masking, can help drown out unwanted noise and create a more pleasant acoustic atmosphere.

3. Modular Acoustic Panels: These panels can be strategically placed to absorb sound, providing a customizable solution for noise control in different areas of a manufacturing facility.

4. Employee Training: Educating employees on the importance of noise control and providing them with proper protective equipment can contribute to a culture of awareness and safety.

In Conclusion

Noise control poses a challenging task for industries, which requires expert guidance. We at VMS Consultants, leading engineering consultancy in Ahmedabad – offer tailored solutions tailored to address the unique needs of industrial segments, specializing in Engineering Architecture & Project Management Services.

With a focus on employee well-being, safety, and environmental considerations, VMS Consultants create industrial spaces that balance productivity with tranquility.

Noise control and acoustic design in manufacturing aren’t just about minimizing decibels; they’re about creating an environment where efficiency and peace coexist.

Are you ready to create a more harmonious manufacturing environment? Contact VMS Consultants today to discover engineering solutions focusing on noise control and acoustics.