Wall and Roof Insulation for Factory Sheds: Ensuring Energy Efficiency and Optimal Performance

General Introduction

In the era of growing industries, energy efficiency and temperature control play an important role in optimizing productivity and ensuring the comfort of factory workers. Wall and roof insulation are vital components that significantly contribute to achieving these goals. In this article, we will focus on the importance of wall and roof insulation for factory sheds and explore the benefits of adopting energy-efficient insulation solutions. From cost efficacy to environmental sustainability, proper insulation is the key to unlocking the full potential of any industrial facility.

Understanding the Importance of Insulation in Factory Sheds

Factory sheds are vast industrial spaces with large surface areas exposed to external weather conditions. Without proper insulation, these industrial structures become vulnerable to excessive heat during the summer and heat loss during the winter. These activities can lead to temperature fluctuations within the premises, creating an uncomfortable working environment for workers and affecting the quality of the goods produced.

Inadequate insulation can result in higher energy costs as the heating, ventilation, and air conditioning systems, also known as HVAC systems, work harder to maintain stable temperatures. Furthermore, such energy waste has a harmful impact on the environment, contributing to increased greenhouse gas emissions and global warming.

The Role of Wall and Roof Insulation

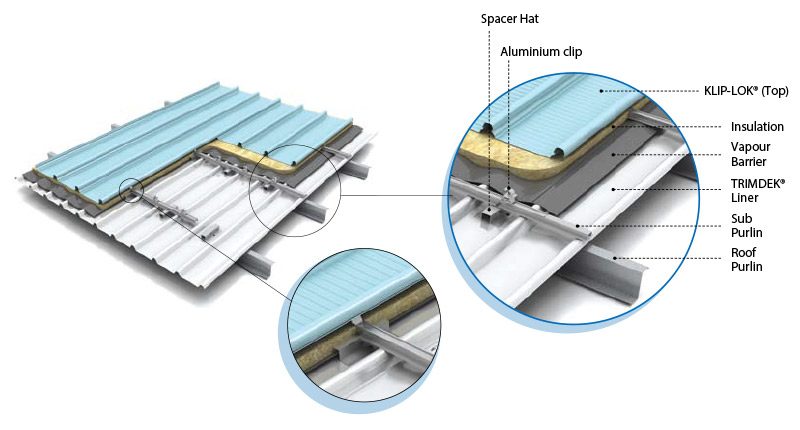

Roof Insulation:

Roofs are the areas where heat gain or loss occurs in factory sheds, primarily. The right roof insulation material can significantly minimize the transfer of heat through the roof, keeping the interior cooler during hot days and warmer during cold days. Insulating the roof area not only enhances energy efficiency but also reduces the strain on Heating, ventilation, and Air Conditioning systems, ultimately leading to lower energy consumption and reduced operational costs.

Wall Insulation:

Insulating the walls of a factory shed is equally important as insulating the roof of a factory shed. Walls that are poorly insulated enable heat to pass through easily, leading to thermal discomfort within the facility. Proper wall insulation eliminates this issue, maintaining a more stable indoor temperature and contributing to a more pleasant working environment with thermal comfort.

Effective Insulation Materials for Factory Sheds

There are a number of insulation materials suitable for factory sheds, each with its own unique properties and benefits. Manufacturers and facility managers need to consider the specific needs of industrial facilities before selecting the appropriate insulation material. Here are some of the most commonly used insulation materials for factory sheds:

Fiberglass Insulation:

Fiberglass is an extensively used and cost-effective insulation material. It consists of fine glass fibers that trap air, retarding heat transfer. Fiberglass insulation is available in various forms, such as batts, rolls, and loose-fill, making it versatile for customized installation requirements. It is a non-combustible material. Fiberglass offers excellent thermal resistance, making it a popular choice for factory sheds.

Spray Foam Insulation:

Spray foam insulation is a highly efficient alternative that offers an airtight seal. It is applied as a liquid that expands and solidifies, filling gaps and cracks in walls and roofs. This property ensures minimal leakage of air, reducing energy loss and enhancing the effectiveness of insulation. Spray foam insulation also provides top-notch soundproofing, improving the acoustics within the factory shed.

Reflective Foil Insulation:

This insulative material consists of layers of foil and polyethylene bubbles that reflect radiant heat. It is commonly taken into account in factory sheds to counter excessive heat gain from sunlight. Reflective foil insulation is lightweight and easy to install, making it a preferred choice for large industrial facilities.

Rockwool Insulation:

Rockwool, also known as mineral wool, is a fire-resistant insulative material. It is made from volcanic rock or steel slag. Rockwool has excellent thermal and acoustic properties and is an ideal choice for environments where fire safety is the foremost priority. Mineral wool is available in different forms, including batts and rigid boards, providing flexibility for different installation needs.

Advantages of Good-Quality Wall and Roof Insulation Energy Efficiency and Cost Savings:

One of the most significant benefits of wall and roof insulation is enhanced energy efficiency. Properly insulated factory sheds require less energy for temperature regulation, resulting in reduced utility bills and overall cost savings. The initial investment in insulation is often recovered through lower operational costs and enhanced productivity.

Enhanced Indoor Comfort:

A well-insulated factory shed ensures a stable and comfortable indoor environment for workers due to thermal comfort. Consistent temperatures contribute to better working conditions, greater employee satisfaction, and enhanced overall productivity. Moreover, proper insulation helps maintain a uniform temperature, reducing the risk of condensation and moisture-related issues in the factory sheds.

Environmental Sustainability:

By minimizing energy consumption and greenhouse gas emissions, proper insulation contributes to environmental sustainability. Sustainable practices are becoming increasingly important for businesses aiming to reduce their carbon footprint and demonstrate social responsibility. Insulation materials with high recycled content further improve the eco- friendly aspect of factory sheds.

Noise Reduction:

In addition to thermal insulation advantages, certain insulation materials also provide soundproofing properties. Industrial structures, such as factory sheds, can be noisy due to machinery and industrial processes. Insulation with superior soundproofing capabilities helps create a quieter and more conducive working environment.

Installation Considerations:

To reap the maximum benefits of insulation, proper installation is vital. Hiring experienced professionals for the installation process ensures a correct fit and reduces the risk of air leakage. Additionally, regular maintenance and inspections should be carried out to rectify and address any potential issues with the insulation, ensuring its long-term effectiveness.

Wrapping Up

Wall and roof insulation are integral components of any energy-efficient and sustainable industrial structure, such as factory sheds. Investing in high-quality insulation materials not only enhances thermal comfort and productivity but also reduces energy consumption and operational costs. By embracing insulation solutions, industries can create a more environmentally friendly footprint while ensuring optimal performance and efficiency in their business operations. As we move towards a greener future, the significance of insulation for factory sheds cannot be overstated. Go for the right insulation material, and your factory shed will reap the rewards for years to come.